Company News

EXCEL Fabrication Stands on Precision

EXCEL's Advanced Pipe Cutting Technology Drives Efficiency and Accuracy in Fabrication Operations

3 min read

With the introduction of new fabrication equipment come opportunities for training on new software systems, reevaluating shop flows, and overall process enhancements for increased efficiency. It’s an exciting time for EXCEL Fabrication and its clients. “Advancements in technology have facilitated a more efficient and knowledgeable workforce when it comes to fabrication.”, says Kyle Munn, Manager of Fabrication Services.

Advanced tracking and reporting tools enable better transparency throughout the manufacturing process, keeping clients informed about the status of their orders. This level of communication increases trust between us and clients,” shares Chad Cohoon. “Not only can we run more streamlined, but our quality assurance, project progress, and productivity are constantly reported in real-time,” Munn explained.

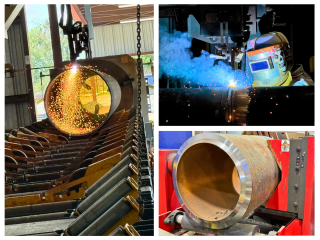

One of the machines purchased by EXCEL Fabrication is the WM-48 Pipe Cutting Machine, which is equipped with advanced features for precise pipe fabrication. This computer-controlled 3D profile-cutting machine accommodates pipes with diameters ranging from 3" to 48" OD. It includes a Mueller CNC cutting torch system, oxy-fueled or plasma, a hydraulic lift deck, and a 6-axis profiling carriage for efficiency. Additional options, such as in-feed and out-feed conveyors, as well as advanced 3D profiling software, enhance its functionality and offer comprehensive solutions for industrial pipe fabrication needs.

“We are excited about the services and projects we can provide to our customers by sometimes thinking outside the box. With a great team like we have here, we will always find the best resolutions.” – Kyle Munn, Manager of Fabrication Services

The oscillatory movement of the cutting head allows for precision cuts for branch connection penetration holes and saddle cuts for pipe supports and stub-ins. In earlier times, humans performed these types of cuts using a layout and torch. The high-efficiency output of the machine enables significant cost savings in labor and materials, which we can pass on to our customers. With the current workload, the facility is processing 140 spools per day, and “every spool in the facility right now is being cut by that machine. There was a big learning curve with the machine, but we’ve had training courses to learn the machine, and we have a great operator working it,” shares Chad.

Another addition is the latest CNC Beveling machine, designed to prepare pipes for welding by efficiently creating various types of bevels. It can work on pipes ranging from 6” to 32” in diameter and can handle different kinds of bevels, such as regular, J-Bev, and U-Bev. This equipment was purchased specifically for large-scale j-bevels required for a specific job. “It’s ideal to do this in-house for our clients now. It’s a safer process, the machine gives us accuracy, and there are cost savings we can pass along,” says Chad Cohoon.

The machine can process pipes with a thickness of up to 3.9” and reface flanges up to 24” in diameter. An average of over 20 bevels are typically completed in a

As EXCEL Fabrication embraces technology and streamlines its operations, the future is brighter than ever for both the company and our valued clients. As the industry evolves, EXCEL Fabrication stands poised and ready to meet and exceed tomorrow's demands with innovation and expertise honed over years of dedicated service.

Advanced tracking and reporting tools enable better transparency throughout the manufacturing process, keeping clients informed about the status of their orders. This level of communication increases trust between us and clients,” shares Chad Cohoon. “Not only can we run more streamlined, but our quality assurance, project progress, and productivity are constantly reported in real-time,” Munn explained.

One of the machines purchased by EXCEL Fabrication is the WM-48 Pipe Cutting Machine, which is equipped with advanced features for precise pipe fabrication. This computer-controlled 3D profile-cutting machine accommodates pipes with diameters ranging from 3" to 48" OD. It includes a Mueller CNC cutting torch system, oxy-fueled or plasma, a hydraulic lift deck, and a 6-axis profiling carriage for efficiency. Additional options, such as in-feed and out-feed conveyors, as well as advanced 3D profiling software, enhance its functionality and offer comprehensive solutions for industrial pipe fabrication needs.

“We are excited about the services and projects we can provide to our customers by sometimes thinking outside the box. With a great team like we have here, we will always find the best resolutions.” – Kyle Munn, Manager of Fabrication Services

The oscillatory movement of the cutting head allows for precision cuts for branch connection penetration holes and saddle cuts for pipe supports and stub-ins. In earlier times, humans performed these types of cuts using a layout and torch. The high-efficiency output of the machine enables significant cost savings in labor and materials, which we can pass on to our customers. With the current workload, the facility is processing 140 spools per day, and “every spool in the facility right now is being cut by that machine. There was a big learning curve with the machine, but we’ve had training courses to learn the machine, and we have a great operator working it,” shares Chad.

Another addition is the latest CNC Beveling machine, designed to prepare pipes for welding by efficiently creating various types of bevels. It can work on pipes ranging from 6” to 32” in diameter and can handle different kinds of bevels, such as regular, J-Bev, and U-Bev. This equipment was purchased specifically for large-scale j-bevels required for a specific job. “It’s ideal to do this in-house for our clients now. It’s a safer process, the machine gives us accuracy, and there are cost savings we can pass along,” says Chad Cohoon.

The machine can process pipes with a thickness of up to 3.9” and reface flanges up to 24” in diameter. An average of over 20 bevels are typically completed in a

As EXCEL Fabrication embraces technology and streamlines its operations, the future is brighter than ever for both the company and our valued clients. As the industry evolves, EXCEL Fabrication stands poised and ready to meet and exceed tomorrow's demands with innovation and expertise honed over years of dedicated service.

Share this article